Metal forming and assembly technology. Overcomes every challenge.

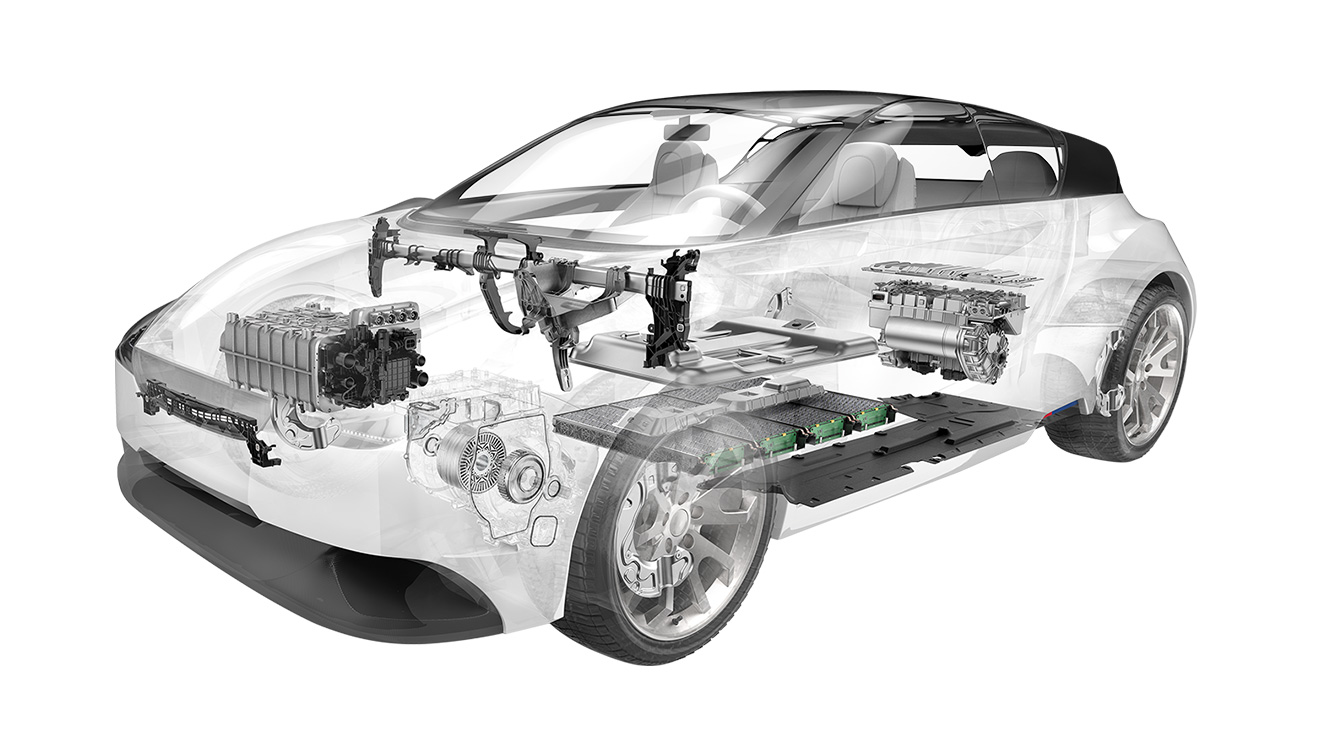

Temperature management, acoustic behavior, safety, electromagnetic compatibility, aerodynamics and cost-effectiveness are key factors that have to be overcome by our metallic stamping and molded parts plus associated assemblies and our shielding systems. They are used in passenger cars and commercial vehicles with electric drive, vehicles with combustion technology, as well as in non-automotive and stationary applications.

Product solutions in the area metal forming and assembly technology.

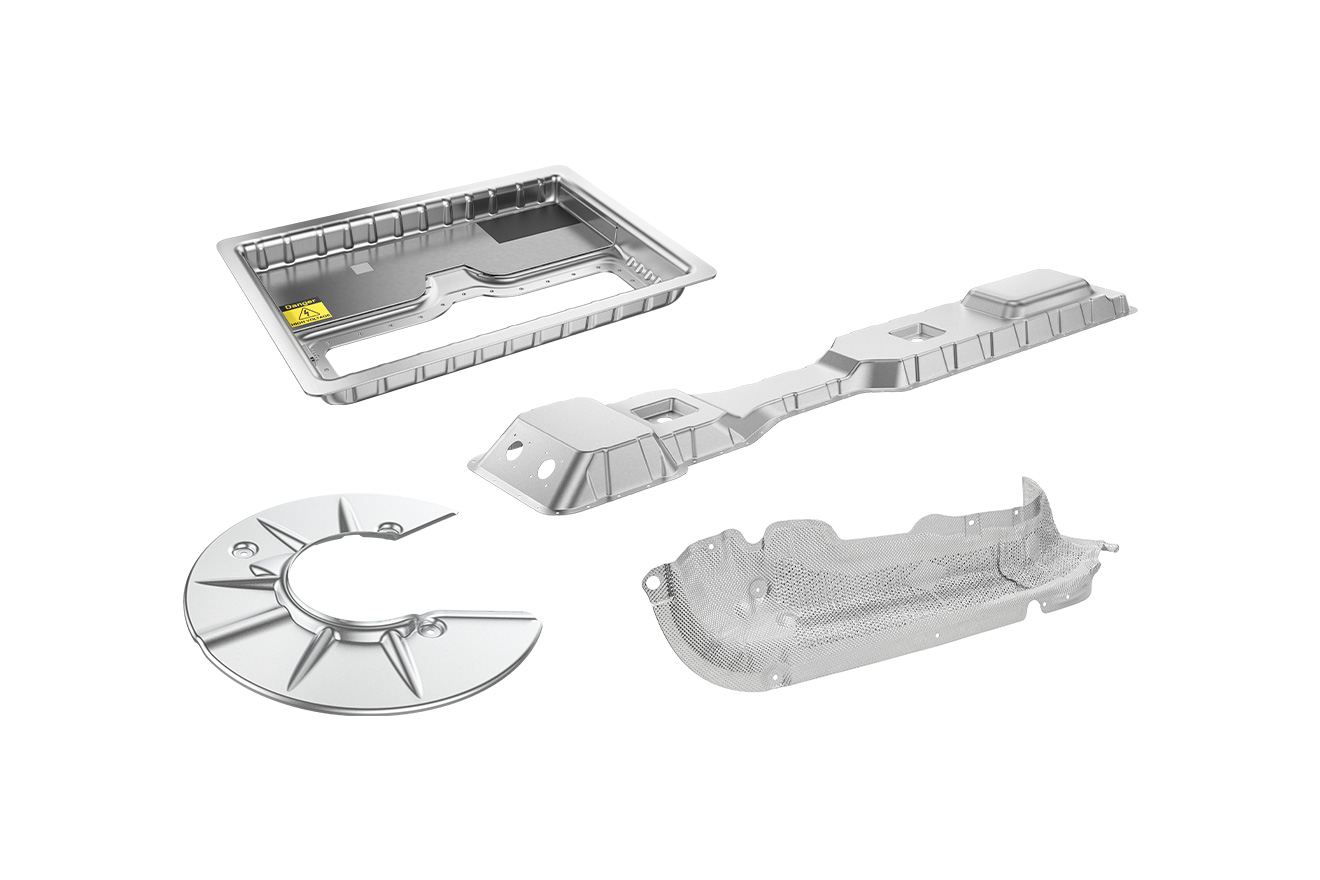

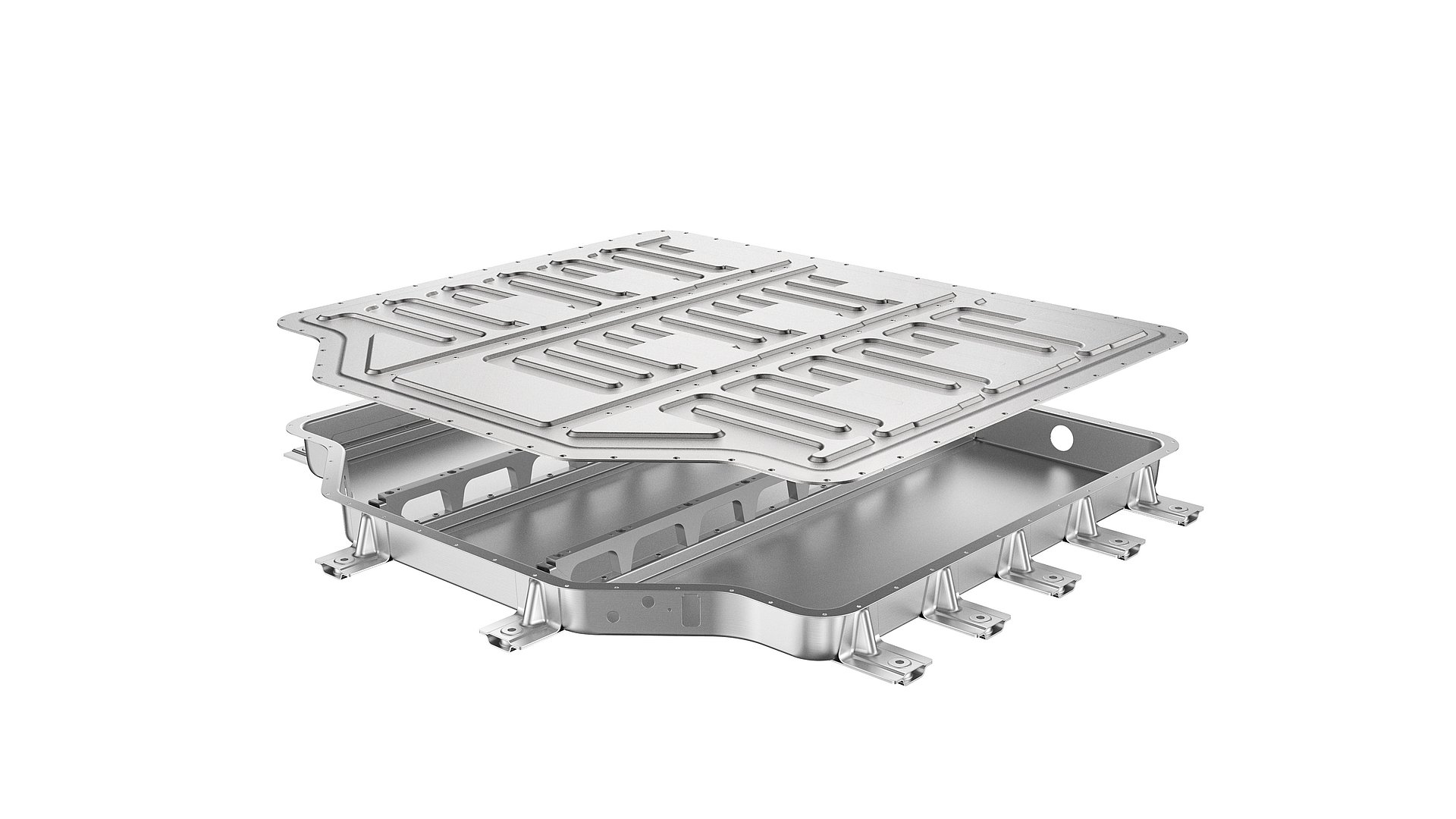

We set standards with our decades of experience in the field of high-precision metal processing, combined with a unique material expertise and high innovative strength. Assembling complex components is one of ElringKlinger's particular strengths: cost-optimized, reliable and close to our customers worldwide. The portfolio covers structurally relevant components and assemblies, such as battery or module housings or covers, inverter covers and adapter fans. Other product solutions include high-voltage shielding, a wide range of covers with functional integration and thermal and acoustic shielding parts for a wide range of applications.

Production in the field of metal forming and assembly technology. Combined expertise.

For ElringKlinger, supplier expertise means reliability from a single source. From development and pre-assembly of attachment components to automated functional and quality control and just-in-sequence delivery of ready-to-install products to the assembly line.

ElringKlinger produces in state-of-the-art assembly cells and production centers - quickly, cost-optimized and in the highest quality. Fully automated presses and robot-based processes enable particularly efficient production, both for large and small series. An online quality check is carried out directly during the production process via camera systems. Produced at numerous locations worldwide, certified according to IATF 16949, ISO 14001 and ISO 9001. We can address customer wishes directly on site. The advantages: clear responsibilities, speed, flexibility, highest quality and all-round service.