Tool technology. Basis for future-oriented products.

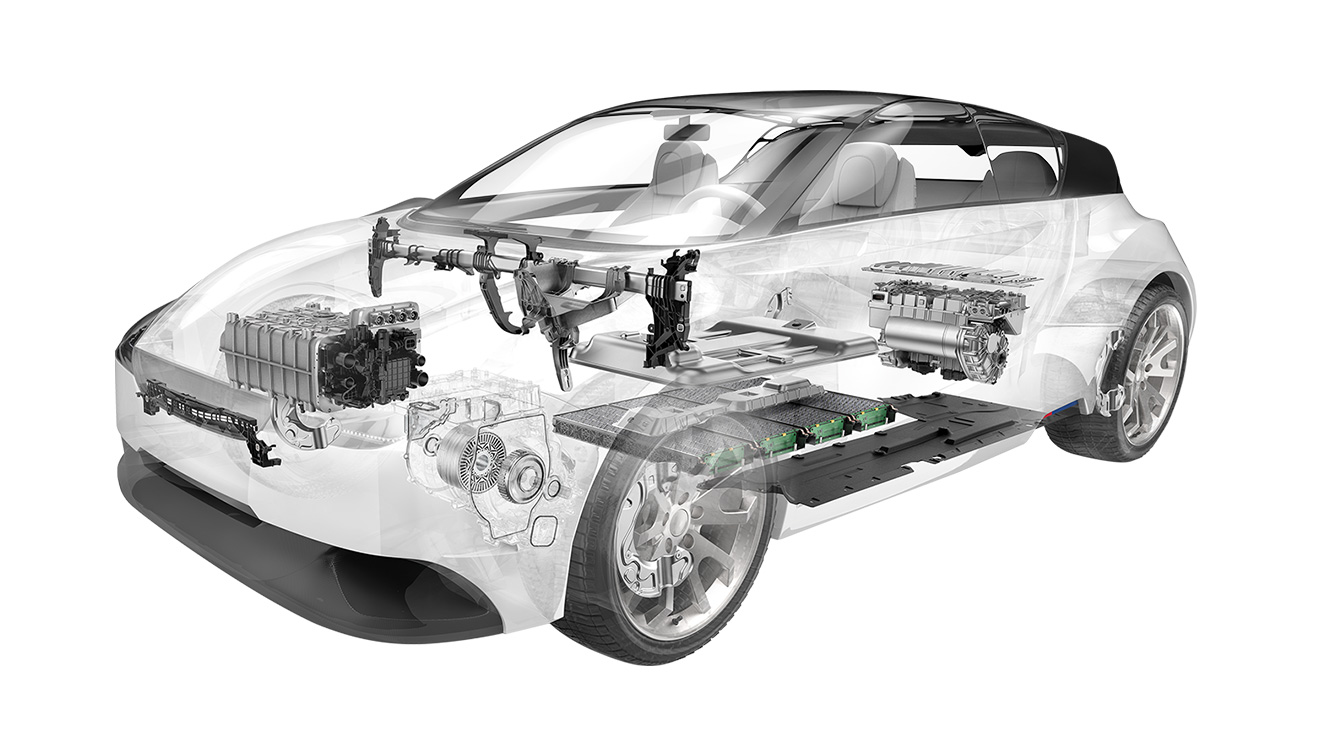

ElringKlinger is a sought-after development partner and series supplier to the automotive industry and other sectors worldwide. An important success factor is our holistic approach, as we manage everything from the first concept through to the finished product. One crucial factor here is our unique know-how in tool technology. At the Toolmaking Technology Center at our Lenningen site, we pool our expertise within the ElringKlinger Group.

In-house toolmakers with extensive expertise

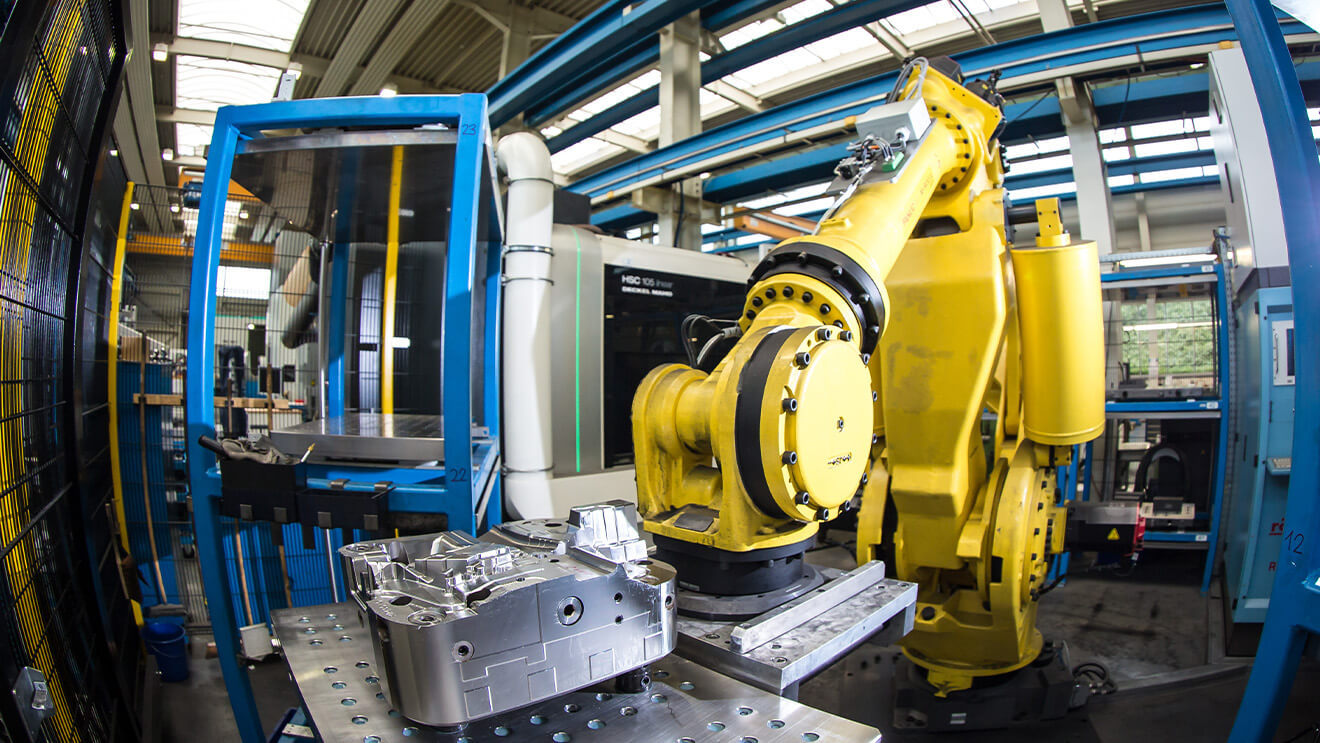

If you are going to manufacture pioneering products, you always need to be a step ahead in toolmaking technology as well. This can rightly be regarded as one of ElringKlinger’s core areas of expertise. After all, its in-house toolmakers manufacture nearly all the necessary production tools themselves. Here, extensive specialist knowledge plays a crucial role in determining whether new developments or processes can even be put into practice in the first place. By working together efficiently with product development and other relevant departments, we can help you reach your goal quickly and economically.

The toolmaking department is much more than just a service provider for ElringKlinger’s individual divisions and plants. It specializes in implementing technically complex 3D product geometries with ultra-precise shapes and dimensions as well as in continuously developing existing technologies and making them more efficient. We are breaking new ground with our “Smart Tool” and are right up to date of the (digital) era: Intelligent, networked tools ensure greater transparency and control, increase global tool performance at ElringKlinger, and ensure the best possible process reliability.

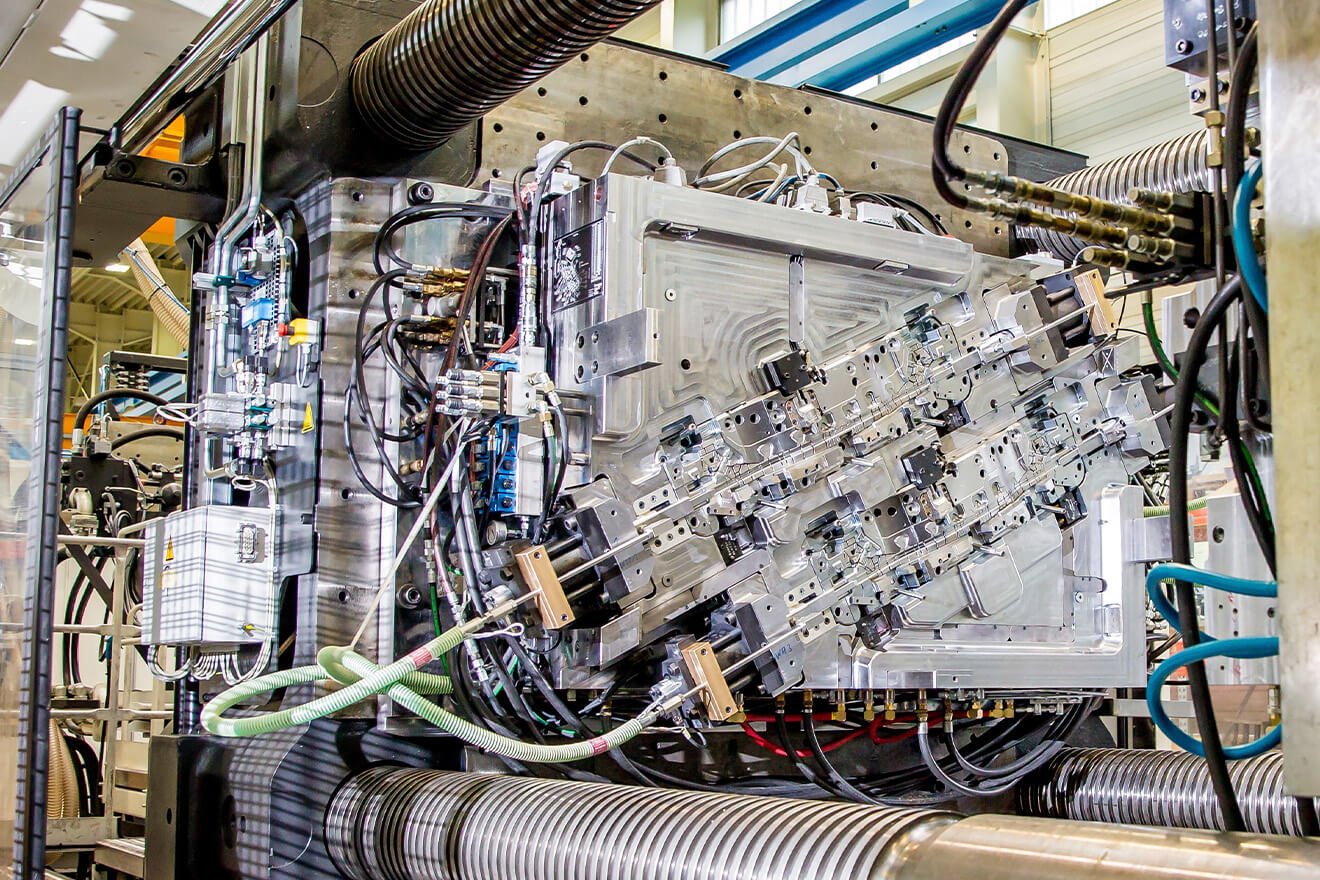

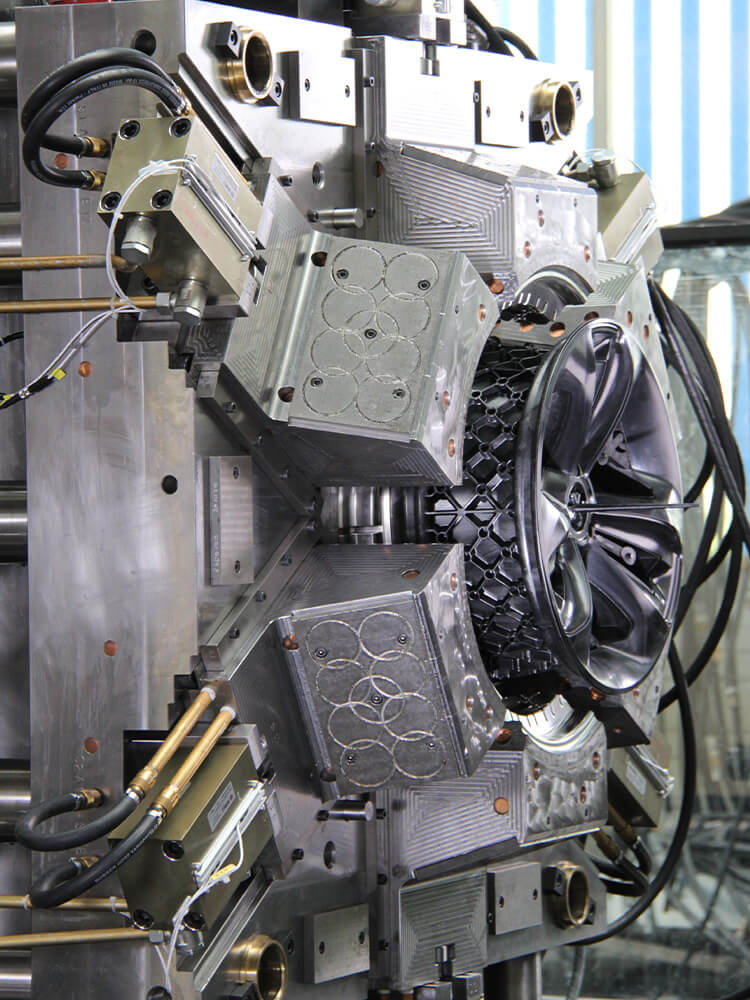

Specialist in plastic injection molding tools – also for external customers

Nobody can do what we do in the field of plastic injection molding and in the processing of fiber composites. After all, the Lenningen site has been successfully active in mold and toolmaking for more than 50 years, both internally for the ElringKlinger Group and for external customers.

System expertise means offering the complete range of services, from product design to high-performance tools ready for series production. In addition, we manage the sampling, technical center, and small-batch production for our customers. The highest quality and cost-effectiveness are also a focus in the manufacture of complete assemblies – all steps, from casting to assembly, are carried out under one roof. Our particular strengths lie in the implementation of complex geometries and sophisticated product solutions, the efficient application and further development of new technologies, as well as our strong customer focus.

Plastic injection molding – our services

- Everything from a single source: product design, production of the tools as well as their sampling and measurement, including all necessary welding procedures and installation work processes

- Tool spectrum: injection molds for production of plastic parts with a shot weight of 20 g to 120 kg

- High-gloss tools for glazing applications

- Core injection-molding method for the production of complex geometries

- Tools for forming and overmolding organo sheets

- SMC and GMT pressing molds (hot-pressing process)

- GID and WID tools

- Hybrid tools for different material combinations

- 2-component tools that save on production steps