Production and environment

ElringKlinger makes targeted use of its environmental and energy management system in order to reduce the environmental impact of its business activities, both at its own locations and increasingly within the value chain. This includes both the certified environmental and energy management system introduced throughout the Group and ongoing measures aimed at conserving resources.

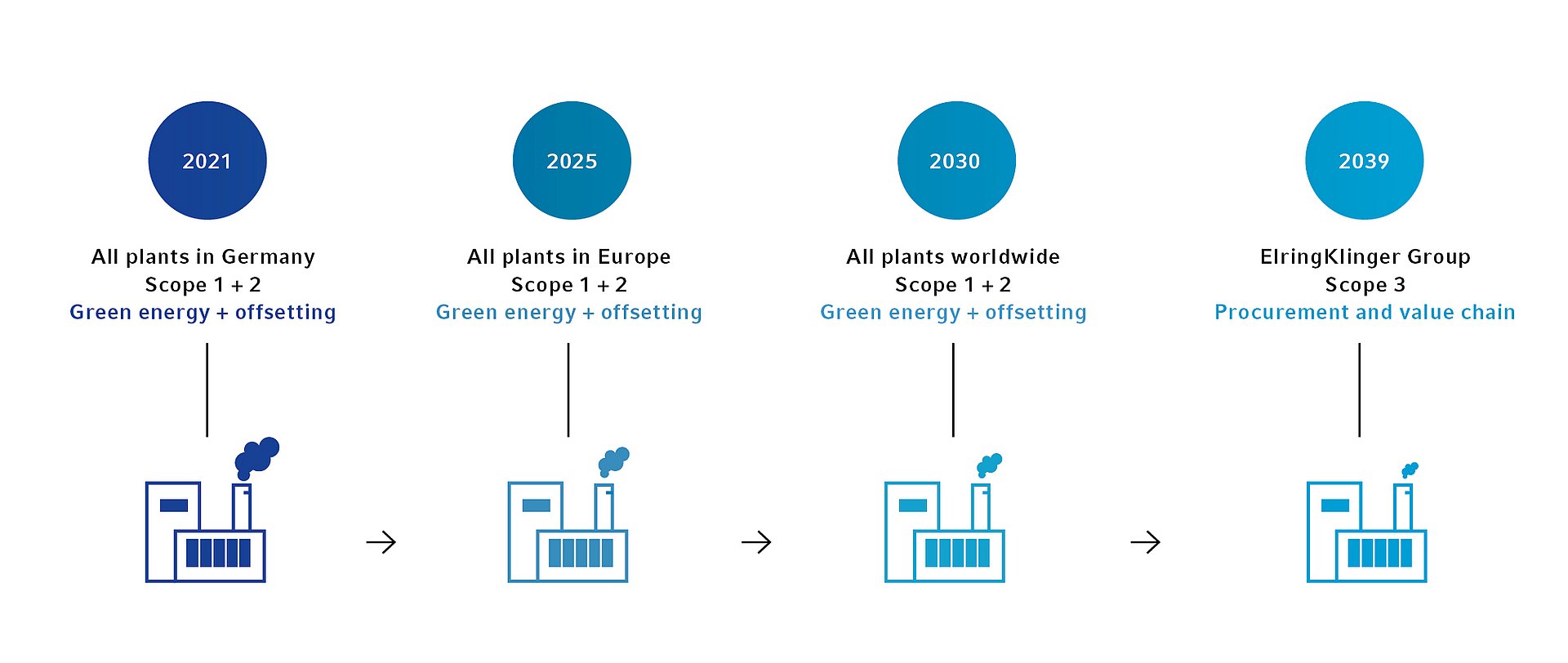

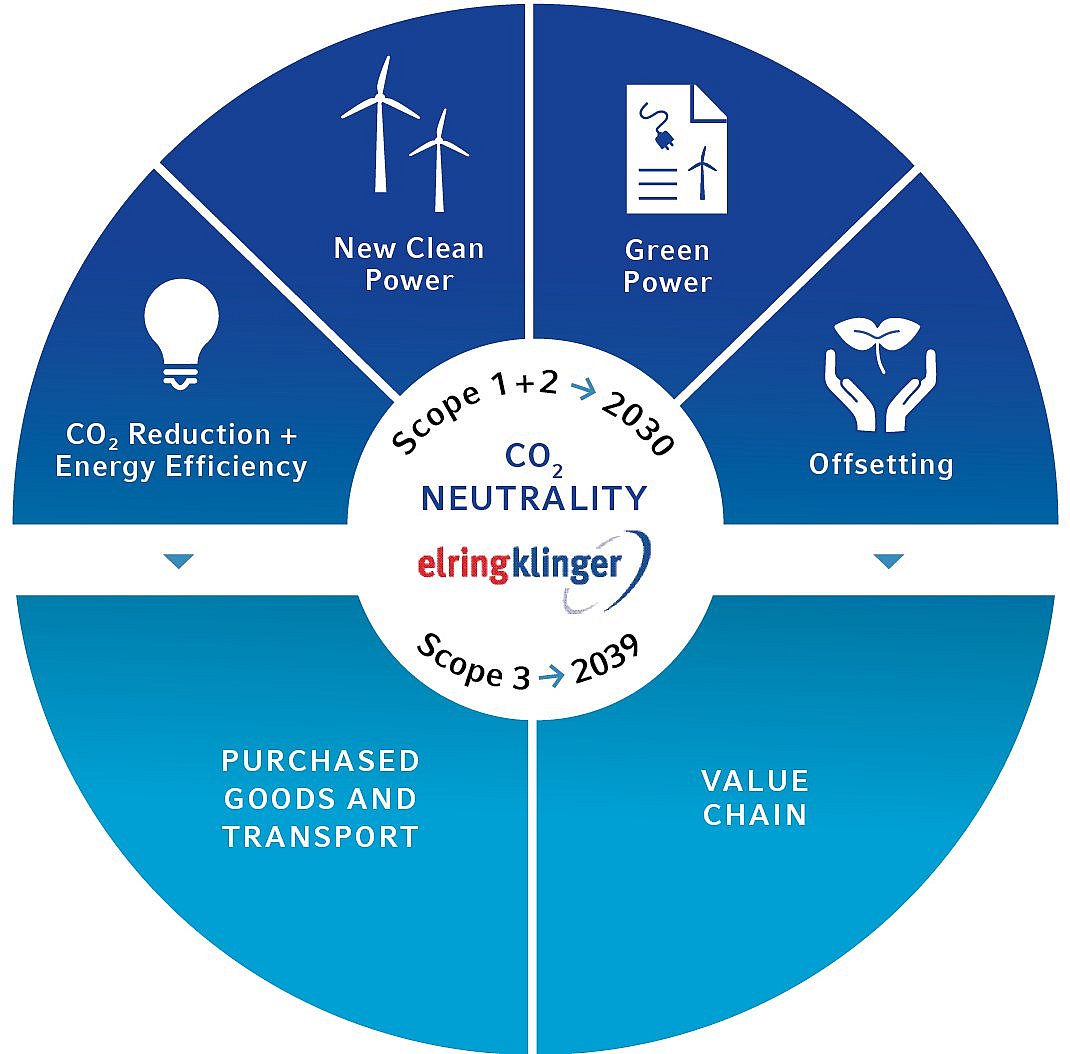

ElringKlinger has been CO2-neutral at all German sites since 2021 - this means that all Scope 1 and Scope 2 emissions have been significantly reduced. The Group offsets absolutely unavoidable emissions by investing in environmental protection projects. By 2025, ElringKlinger plans to achieve carbon neutrality at all European sites and by 2030, all sites worldwide are to achieve carbon-neutral production. At the same time, Scope 3 emissions, i.e. all emissions generated along the entire value chain, will also be reduced. To structure the large number of measures being implemented in the Group, a total of four different areas of action have been defined, which are being implemented at all locations. These include increasing energy efficiency in all buildings and facilities, expanding the use of renewable energies, switching to green electricity and offsetting completely unavoidable CO2 emissions by investing in external CO2-reducing projects.The Group has aligned the climate targets it has set with the science-based climate targets of the Scinece Based Target Initiative (well below 2 °C global warming).

In the first area of action, ElringKlinger aims to continuously increase the energy efficiency of its existing plants and buildings. To this end, the production sites are required to reduce CO2 emissions by at least 2.5% per year compared to the base year 2019. This includes, for example, optimising existing processes and consistently avoiding fossil fuels. In the second area of action, the Group is reviewing the installation of systems to generate its own renewable energy wherever this is technically feasible and economically viable. In the third area of action, all electricity supply contracts are being switched to electrical energy generated from environmentally friendly renewable energy sources. All unavoidable CO2 emissions are offset through investments in climate protection projects. In addition, around 1% of planned investments are spent annually on measures to increase energy efficiency. The focus is then on both the projects that achieve the greatest CO2 reduction per euro paid and the measures that achieve significant energy savings. Each change brings the Group closer to its goal of climate neutrality.

Through the ISO 50001 matrix certification scheme that ElringKlinger has introduced at its European production locations, the Group has intensified its integrated approach to energy flows and established an extensive metering infrastructure at individual production plants. As a result, previously unused energy efficiency potential can be unlocked, energy costs reduced and greenhouse gas emissions (e.g. CO2 emissions) cut. The energy management system therefore makes an important contribution to environmental protection. ElringKlinger has already been using green electricity in all its German production plants since 2021. By 2030, all other production plants will have been converted globally. At the same time, the Group is increasingly focusing on generating its own green electricity, e.g. by installing PV systems at its own sites.

ElringKlinger is part of the Baden-Württemberg Climate Alliance. With this agreement, the Climate Alliance partners declare that they will support each other in achieving the political and corporate climate protection targets and work together in a cooperative manner.