Lightweight technologies. Multifunctional. Durable. Efficient.

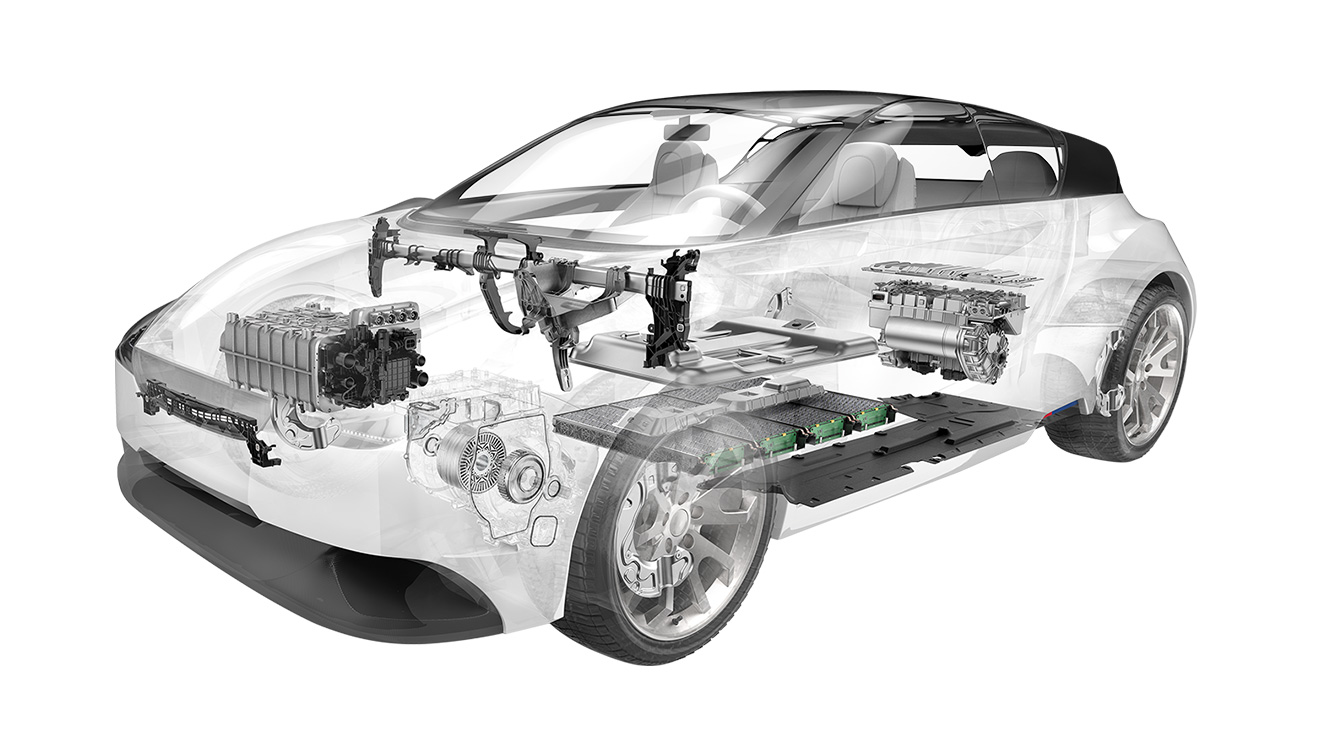

Improved safety, more comfort, better driving dynamics: Modern vehicles have a lot to offer. Intelligent lightweight design is necessary to ensure that these extra features and performance options do not drive the vehicle weight up. Customized lightweight components from ElringKlinger can be used throughout the vehicle. We also use our expertise specifically for applications in battery systems, fuel cells and drives.

Lightweight technologies. Tailor-made solutions.

Lightweight construction is one of the key technologies in the automotive industry and other sectors. Our system expertise sets us apart here, too, and we have mastered a wide range of manufacturing processes in lightweight plastic construction. We offer tailored product solutions of the highest quality for our customers. The focus is on weight reduction, functional integration and optimization, robustness and efficiency. At ElringKlinger, everything comes from a single source: Product development and testing, material expertise, process development, toolmaking, production and end-of-line testing.

Intelligent lightweight construction. For all drive types.

For ElringKlinger, intelligent lightweight construction is more than just reducing weight. We use lighter materials – fiber-reinforced plastics, thermosetting plastics, organic sheet materials, and metallic materials such as aluminum and magnesium – in combination with state-of-the-art manufacturing processes. This opens up the option of increased function integration, which can reduce the total number of parts. Development times and costs are also reduced in addition to weight and material. Lightweight components from ElringKlinger impress with the highest quality and maximum customer benefit.

The advantages at a glance

- High cost effectiveness

- Many functions integrated

- Function check of complete module

- Improved NVH characteristics

- Design flexibility

- Shorter development times

- Reliable, easy assembly

- Recyclability

- Resource efficiency

Development and production. Everything from a single source.

Holistic thinking drives innovations, opens up new possibilities and creates synergies. Our success as a system supplier for lightweight construction is also based on this: Everything comes from a single source, from the first concept to the finished product. We use our comprehensive development, process and manufacturing expertise to develop tailored lightweight components for the drive system, body and underbody. Production takes place at numerous locations worldwide - locally at our customers' premises.

Process and tool expertise. Experience puts us ahead of the game.

At ElringKlinger, a large share of the production tools used are designed and manufactured by our in-house toolmaking. For lightweight components, we make particular use of the expertise of our competence center in Lenningen, Germany, which has specialized in mold and tool manufacture, plastic injection-molding and the processing of fiber composites for over 50 years.

![[Translate to English:] Prozess- und Werkzeugkompetenz. Erfahrung schafft Vorsprung. [Translate to English:] Prozess- und Werkzeugkompetenz. Erfahrung schafft Vorsprung.](/fileadmin/data/images/01-produkte-technologien/leichtbau/elringklinger-prozess-werkzeugkompetenz-1320x880.jpg)