In focus: Components for electrolyzers

The electrolysis process breaks down various chemical compounds into their individual components using electricity. Accordingly, this can be used to produce the raw material for hydrogen-based applications. The electrical energy used is converted into chemical energy and stored in hydrogen. In case the hydrogen is produced from electricity from renewable sources, a completely emission-free mobility is feasible. To achieve high electrical efficiency, high-quality seals and components made from high-performance plastics are required.

ElringKlinger Engineered Plastics develops and manufactures frame gaskets with a diameter of up to 3 meters for electrolysers, for example.

Plastic components

Our subsidiary ElringKlinger Engineered Plastics has a wide range of high-performance plastics and validated production processes. This means that small batches, prototypes, and large batches can all be produced economically. Our in-house series processes in machining and plastic injection molding make us an ideal partner for scaling up electrolysers. Our portfolio includes, for example, seals and components up to a diameter of 3 meters as well as hoses and pipes made of fluoropolymers. More information about components for electrolysers can be found here.

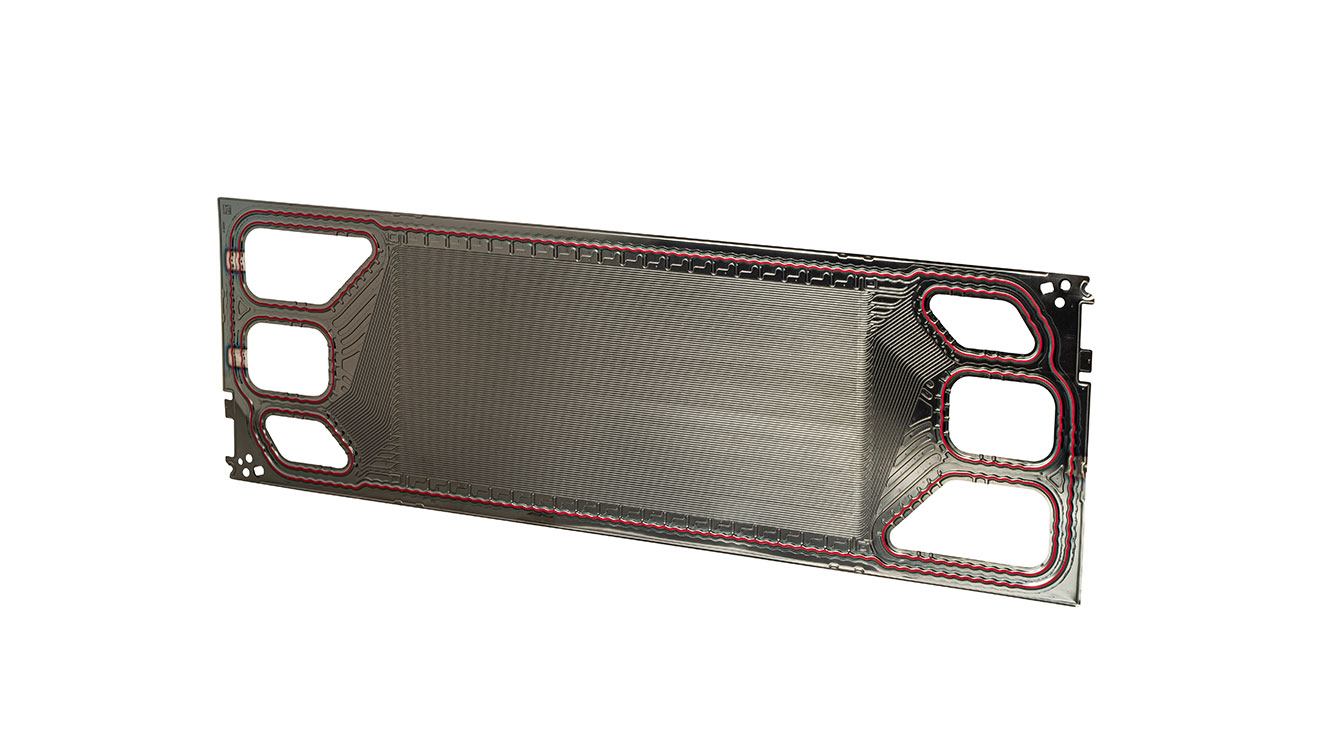

Metal bipolar plates

Our subsidiary EKPO Fuel Cell Technologies offers bipolar plates made of corrosion-resistant steel in combination with various coating options, with major advantages in terms of cost-efficiency, power density, and cold-start capability of fuel cells. A functional, high-performance design is developed specifically to meet customer requirements. Production takes place using high-precision, high-volume production-compatible progressive tools in a fully automated, interlinked production process.

How it works: PEMFC stacks consist of alternating stacks of membrane electrode assemblies (MEAs) and bipolar plates. They are interspersed with porous layers that serve to distribute the gas and transfer the electric current. The bipolar plate separates the media and distributes them within the stack. It also ensures uniform cooling of the stack and transfers the electric current to the adjacent cells.