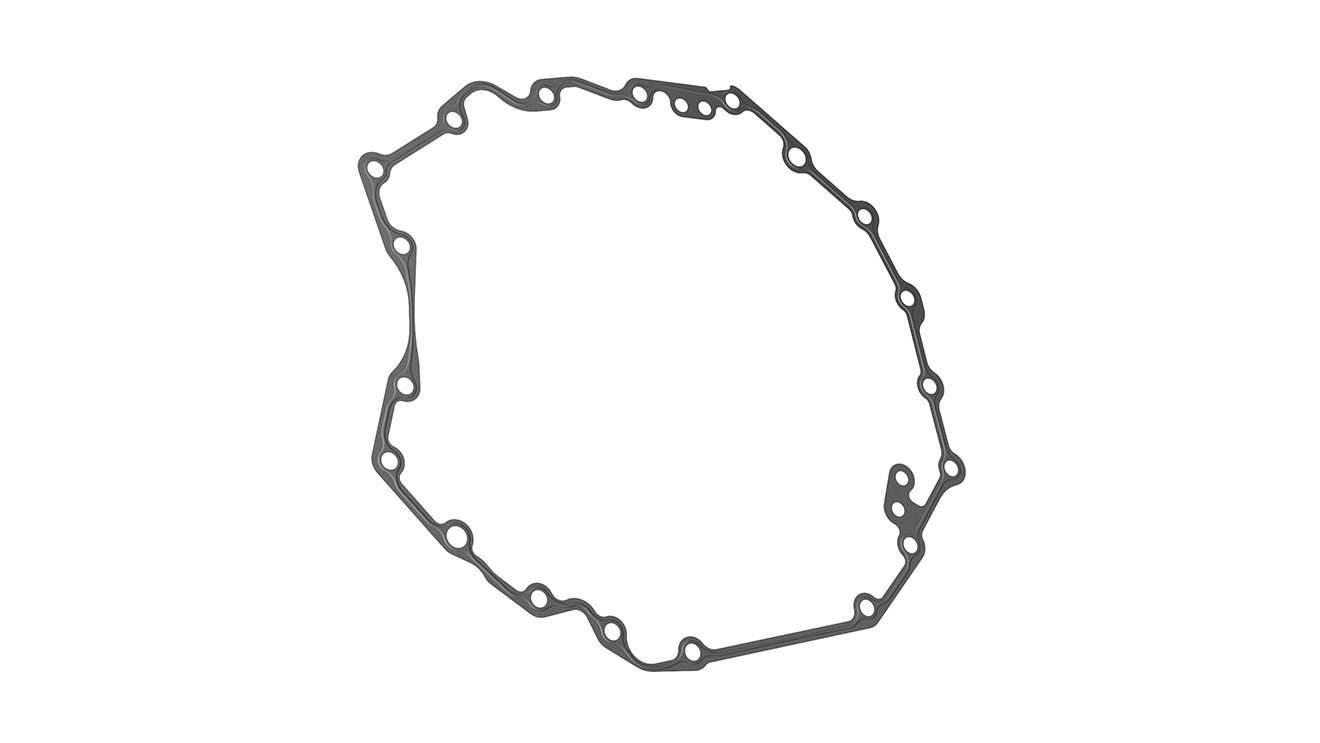

MetaloSeal™ metal bead gaskets

This highly effective sealing system is based on metallic carrier materials, onto which an elastomer function coating is applied. Metal beads ensure line pressing, which concentrates the sealing force where it is required. Adaptability is one of the great advantages of Metaloseal™: different metals can be combined with different elastomer types, precisely aligned to the relevant application. Highly elastic with minimal assembly forces. The latest development is an electrically conductive coating that is used in particular for EDUs and battery applications with high requirements for electromagnetic shielding (EMC).

Metaloseal™ sealing systems are used in temperature ranges from - 40 °C to + 800 °C and in pressures up to 200 bar. Because they are installed in the main load gasket, they enable a simplified sealing flange design without a groove.

The advantages of MetaloSeal™

- Resistant to a wide range of media such as gas, oils, fuels and coolants

- Excellent adaptability in the event of severe distortions or sealing gap vibrations, with increased friction value for force transmission and with reduced friction value that allows thermal expansion

- Pre-assembly elements can be integrated to ensure secure fastening of the gasket even overhead and for Poka-Yoke solutions

- Other elements, such as heat shields or fabric filters, can be integrated

- Reduced number of parts and simplified assembly processes at the customer's premises