Elastomer and metal-elastomer gaskets

Whether with or without metal carrier material, both gasket designs stand for optimal function reliability and efficiency. The special feature: ElringKlinger develops the elastomer materials used in-house.

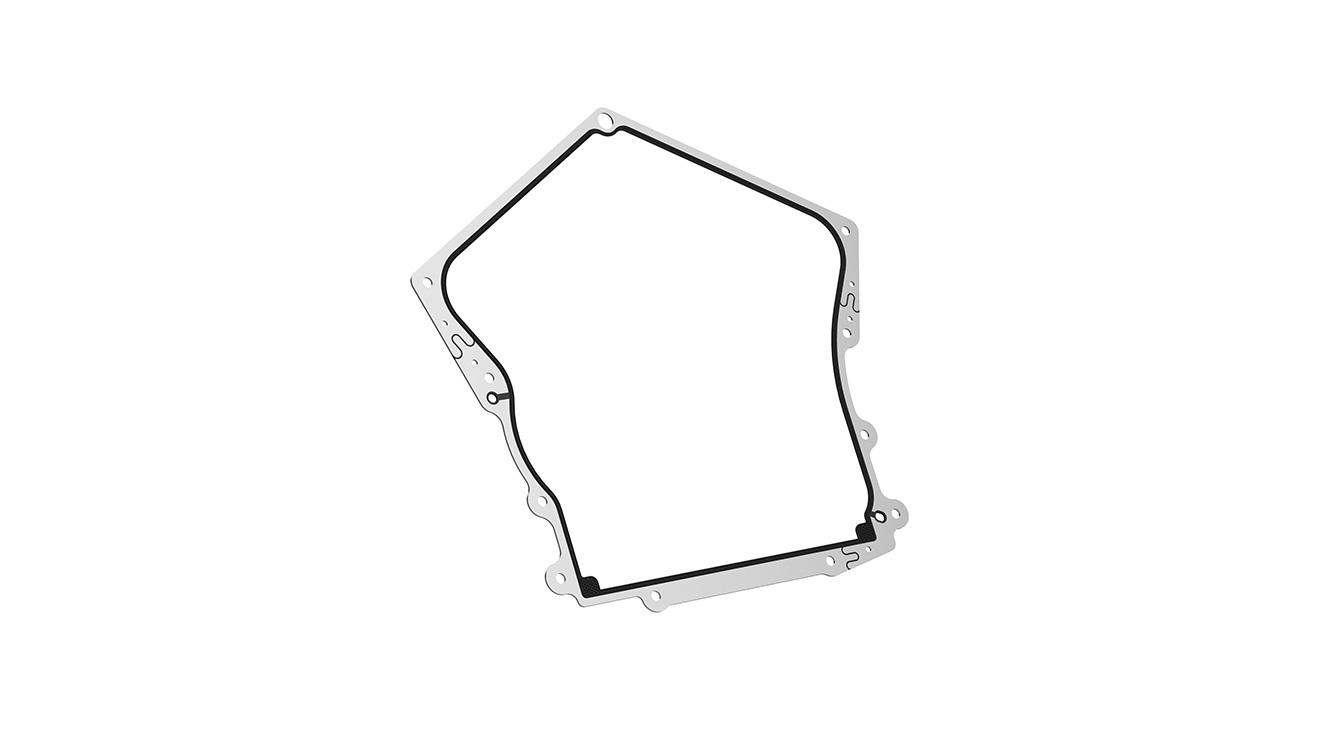

Metal-elastomer gaskets

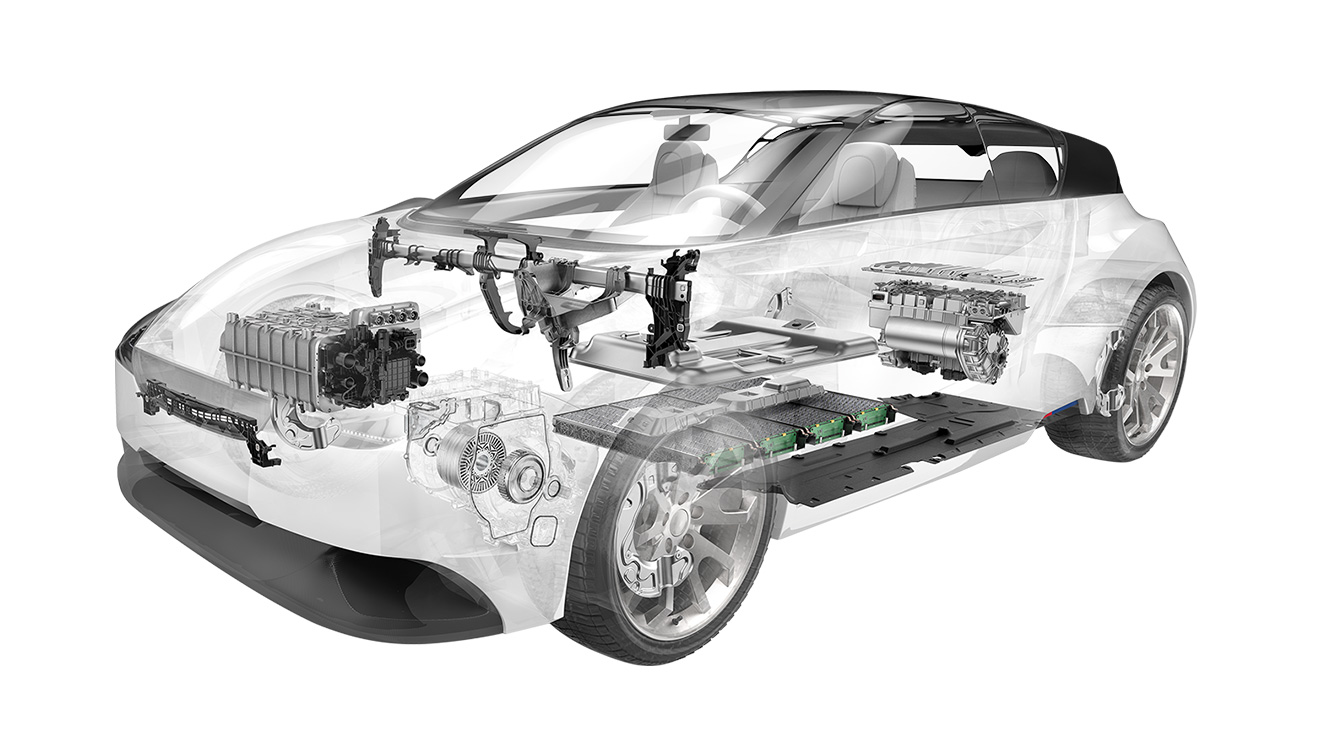

Metal-elastomer gaskets are used for highly stressed components such as electric drive units, battery storage systems or engine and transmission components. They consist of a metal carrier with vulcanized elastomer profiles. The elastomer materials used are developed in-house by ElringKlinger and tailored to the relevant requirements. Thanks to state-of-the-art process technology and injection molding technologies, different materials can be joined to a metal of plastic carrier. This enables the optimal material to be used for every medium to be sealed.

The advantages

- Reliable sealing even with low sealing pressures

- Equalization of high component tolerances

- Three-dimensional shaping

- Reduction of the screw force and number of screws

- Acoustic component isolation

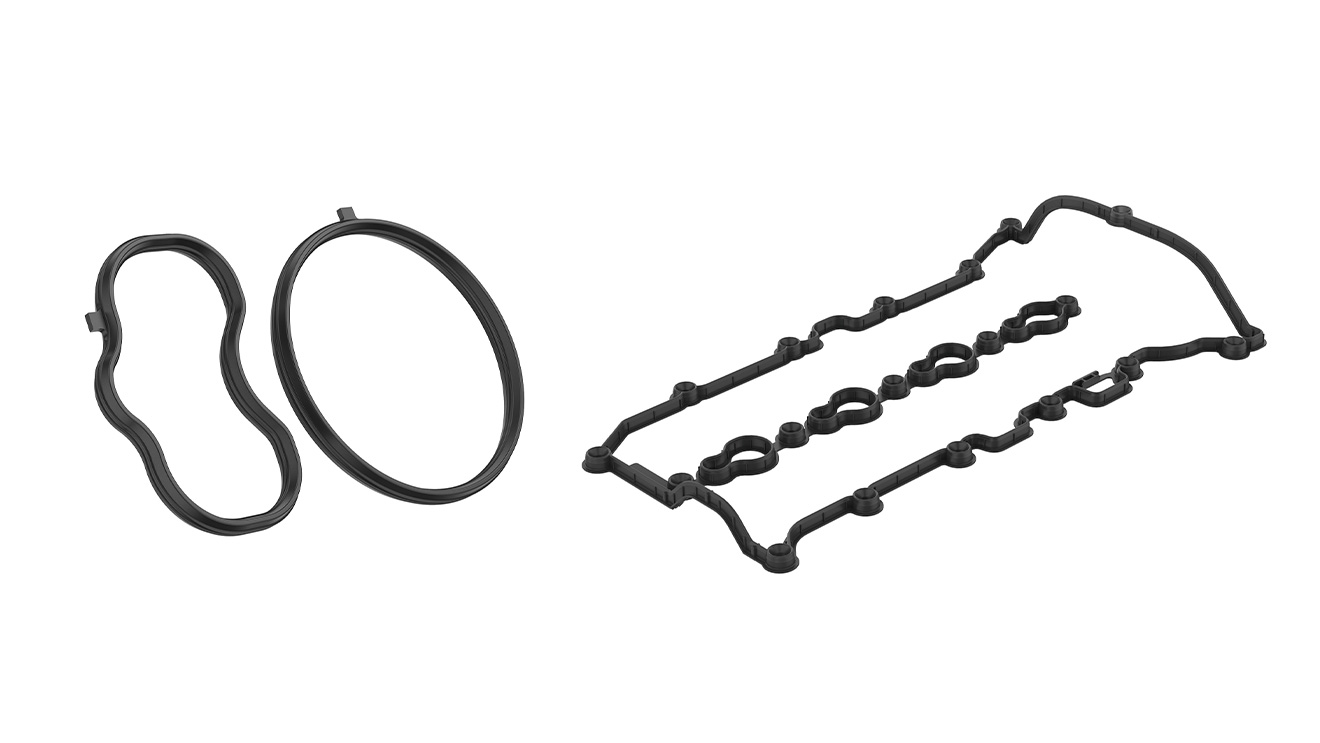

Elastomer gaskets

In principle, elastomer gaskets with specifically coordinated profile geometries can be used at all sealing points in battery systems or in the drive train. For force-transmitting connections, they must be mounted in the force shunt, for example through component grooves or screw supports. The special profile geometries guarantee maximum function with the lowest possible sealing pressures.